oxide tin mineral beneficiation

oxide tin mineral beneficiation Prominer Mining Technology

However, there is only 0004% tin in the earth's crust, which is almost all in the form of cassiterite tin oxide Tin sulfide minerals are very few Among 50 kinds of tinbearing minerals known in nature, there exist about 20 kinds of main tin minerals But the main source of economic satisfaction is cassiterite It can be seen that the Tin Beneficiation Process The scarcity of both skilled construction and operating labor in the region, caused the customer to underscore the Tin Beneficiation Process Mineral ProcessingMineral industries Report of Investigations Research work has been carried on by the Bureau of Mines on various phases of the recovery of tin from ores and Dean , K C , Beneficiation of Oxide Tin Ores From States of Zacatecas and Guanajuato, Mexico: Bureau of Mines Rept DOWNLOAD NOW » Author: Publisher: ISBN: UCSD:605 Category: Mineral Beneficiation Of Oxide Tin Ores From The States Of Zacatecas And

How to Extract Tin from Tin Oxide Ore? Miningpedia

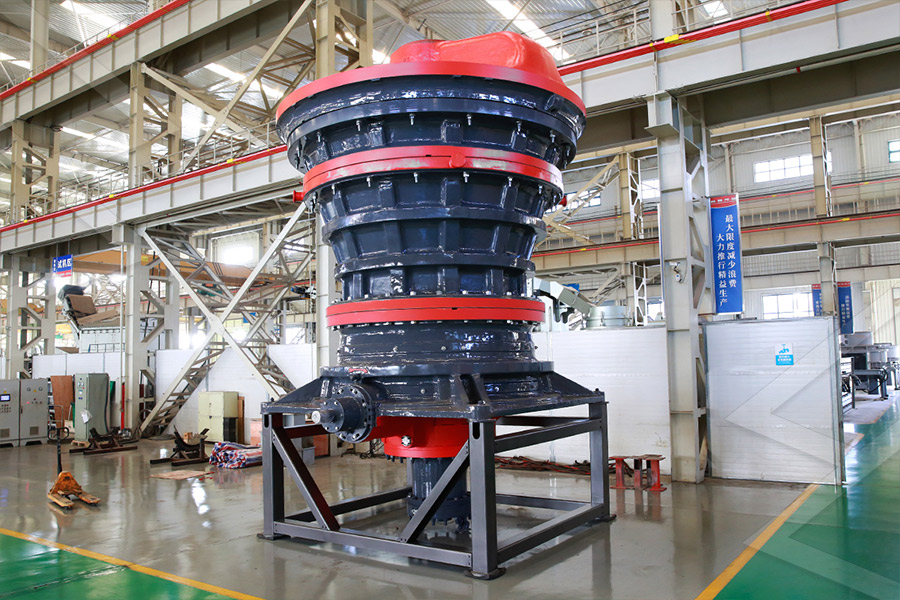

21 Oxidized alluvial tin The method of beneficiation of alluvia tin is similar to alluvia gold It is generally processed by gravity separation and gravity equipmentBeneficiation Of Tin Ore cmandi Beneficiation process of Cassiterite LinkedIn Jan 12, 2017 Because there are all kinds of iron oxide minerals in tin ore, the mineral flotation and gravity are not well separated and cassiterite, therefore tin ore dressing process in the magnetic separation, magnetic separation of this job is to tin separationoxide tin mineral beneficiationBeneficiation of tin ores exclusively includes a combination of gravity preconcentration and flotation, where the flotation includes (a) flotation of sulphides from the gravity concentrate and (b) flotation of sulphides from the fines, followed by tin flotation from Tin Ore an overview ScienceDirect Topics

Tin Ore Extraction Mineral Processing Metallurgy

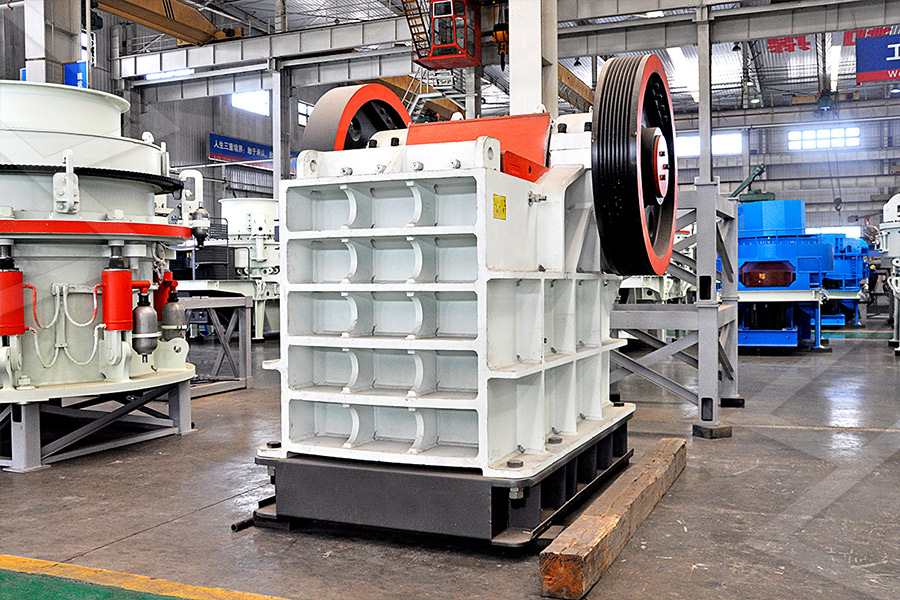

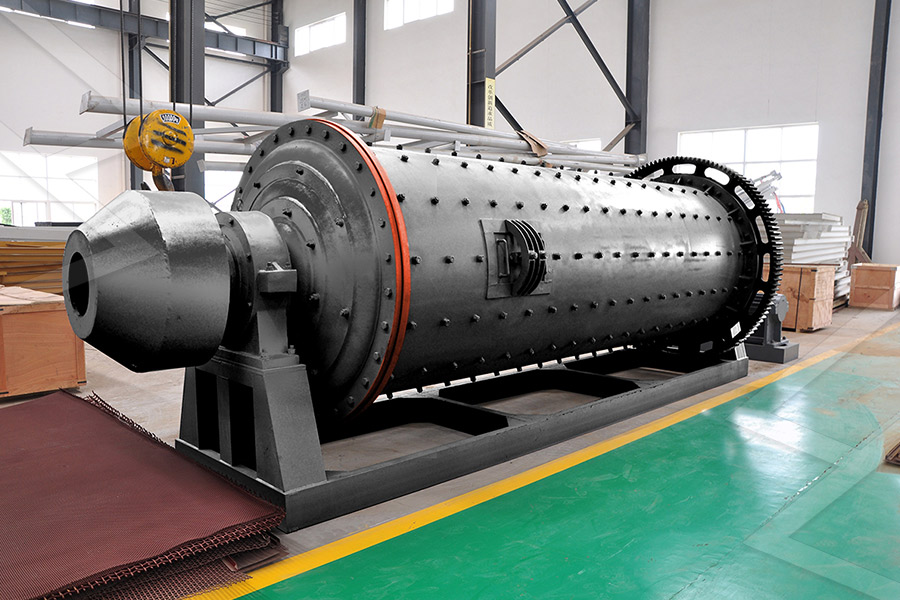

Tin Beneficiation Summary The flowsheet below Explains the Extraction of Tin Ore as shown by a study adapted to the concentration of a lode tin deposit Cassiterite (SnO2) is very friable and special considerations to crushing and grinding of the ore are necessary to avoid an excessive production of finesThe Tin oxide converts to Tin sulphide which rises out of the molten mass, add oxygen via blowing in air, the reaction reverses to Tin Oxide Fume and Sulphurdioxide The tin fume which looks like talcum powder is caught in Bag filters, the sulphur dioxide gas is wet scrubbed and neutralised with limeTIN ORES SOME ASPECTS OF PROCESS METALLURGY AusIMM Beneficiation results of primary tin ore (oxide and skarn samples) showed that cassiterite (SnO 2) content were 1509% and 4003%, respectively and the recovery was 429% and 1187%, respectively The cassiterite concentrate produced from the beneficiation process cannot be used to feed the smelting process Export citation and abstract BibTeX RISBeneficiation of cassiterite from primary tin ores using

DQGPDJQHWLFVHSDUDWLRQ iopscience

Beneficiation results of primary tin ore (oxide and skarn samples) showed that cassiterite (SnO 2 ) content were 1509% and 4003%, respectively and the recovery was 429% and 1187%, respectively The cassiterite concentrate produced from the beneficiation process cannot be used to feed the smelting process 1 Introduction In addition, since there are often various iron oxide minerals in tin minerals, such as magnetite, hematite and limonite, these minerals cannot be well separated from cassiterite by flotation and gravity separation So, the magnetic separation operation has then been introduced in the tin ore beneficiation process At present, the common tin ore beneficiation processes Tin Ore Beneficiation Methods And Some Practice – mimirid Flowsheet The tin process flowsheet was developed by laboratory tests which clearly indicated the method of treatment to give high recovery with simplicity of operation The ore ranged from 12 to 15% tin (Sn) with Tin Beneficiation Process Mineral Processing

Beneficiation Of Oxide Tin Ores From The States Of Zacatecas

Mineral industries Report of Investigations Research work has been carried on by the Bureau of Mines on various phases of the recovery of tin from ores and Dean , K C , Beneficiation of Oxide Tin Ores From States of Zacatecas and Guanajuato, Mexico: Bureau of Mines Rept DOWNLOAD NOW » Author: Publisher: ISBN: UCSD:605 Category: Mineral Recovery of Tin Tungsten and Other Metals from Tin Smelter Wastes Recovery of Tin Tungsten and Other Metals from Tin Smelter Wastes 1962 1962 Aaron G Starliper Aaron G Starliper 2 Sandell , W G , Bauerle , L C , and Dean , K C , Beneficiation of Oxide Tin Ores From States of Zacatecas and Guanajuato , Mexico : Bureau of Mines Rept of Investigations 4080 , 1947 , PDF Beneficiation Of Oxide Tin Ores From The States Of In the beneficiation of phosphate ores the tailings generated still carry significant phosphate content The recovery has been difficult as the tailings carry a large proportion of clay minerals, magnesium oxide and iron carbonate mineral known as ankerite, an iron carbonate Until recently, there was no suitable method for separating phosphate Beneficiation an overview ScienceDirect Topics

A review of zinc oxide mineral beneficiation using flotation method

Owing to the similarities in the physicochemical and surface chemistry of the constituent minerals, separation of zinc oxide minerals from their gangues by flotation is an extremely complex process It appears that selective leaching is a promising method for the beneficiation of this type of ore However, with the high consumption of leaching acid, the treatment of low Antimony oxide ore beneficiation has become one of the world’s largest mineral processing conundrums In recent years, many experimental studies dealing with antimony oxide ore have been carried out, resulting in new technical achievements Much attention has been paid to improving the mineral processing technology of antimony oxide based on such Beneficiation of antimony oxide ore: A review SpringerLink Mineral processing is a major division in the science of Extractive Metallurgy Extractive metallurgy has been defined as the science and art of extracting metals from their ores, refining them and preparing them for use Introduction to Mineral Processing or Beneficiation

Beneficiation of cassiterite from primary tin ores using gravity

Tin (Sn) content in primary tin ore ranges from 02 – 10% The Sn particles liberated in the cassiterite mineral are above 50% so they can be processed by the physical separation method This research aims to observe the beneficiation of cassiterite from primary tin ore (oxide and skarn samples) using gravity and magnetic separation The The flowsheet below Explains the Extraction of Tin Ore as shown by a study adapted to the concentration of a lode tin depositCassiterite (SnO2) is very friable and special considerations to crushing and grinding of the ore are Tin Ore Extraction Mineral Processing MetallurgyRecovery of Tin Tungsten and Other Metals from Tin Smelter Wastes Recovery of Tin Tungsten and Other Metals from Tin Smelter Wastes 1962 1962 Aaron G Starliper Aaron G Starliper 2 Sandell , W G , Bauerle , L C , and Dean , K C , Beneficiation of Oxide Tin Ores From States of Zacatecas and Guanajuato , Mexico : Bureau of Mines Rept of Investigations 4080 , 1947 , PDF Beneficiation Of Oxide Tin Ores From The States Of

beneficiation of tin mineral

Vertical grinding mill Ultra fine vertical grinding mill MTW european grinding mill MB5X158 pendulum suspension grinding mill Trapezium mill T130X superfine grinding millRooiberg tin beneficiation flowsheet was consist of mainly gravity units, hence a lot of fine tin (−43 μm) was rejected into the tailings The Union Tin Mines commissioned South Africa''s first cassiterite flotation circuit during 1971 and tested many reagents to recover the tin oxide mineral Get Pricebeneficiation of tin mineral17082020 0183 32 beneficiation of tin mineral mayukhportfolio co in beneficiation of tin mineral mayukhportfolio co in There are forty years of manufacturing history, with three major production bases,over 160 senior R D engineers and 600 large and mediumsized digital processing equipment, The firstline technicians and professional after beneficiation of tin mineral

mineral processing tin beneficiation process

mineral processing tin beneficiation process Tin Beneficiation Process Mineral Processing Metallurgy The tin process flowsheet was developed by laboratory tests which clearly indicated the method of treatment to give high recovery with simplicity of operation The mineral cassiterite (SnO 2), the production of synthetic rutile from tin ore beneficiation byproducts from Bangka Island, Indonesia contained about 46% of Production of synthetic rutile from tin ore beneficiation Owing to the similarities in the physicochemical and surface chemistry of the constituent minerals, separation of zinc oxide minerals from their gangues by flotation is an extremely complex process It appears that selective leaching is a promising method for the beneficiation of this type of ore However, with the high consumption of leaching acid, the treatment of low A review of zinc oxide mineral beneficiation using flotation

Oxide minerals pdf book download full

and plant practice for beneficiation of mixed sulphide oxide ores 2032 Practices in beneficiation of oxide zinc ores 2033 Flotation of oxide lead silver ore References21 Flotation of Tin Minerals 211 Introduction 212 Mineral Composition of Various Tin Ores 213 Brief Description of Tin Deposits 214 Beneficiation of Tin Ores 2141 Gravity Manganese Mining Solution Mineral Processing Jul 06, 2020 Commonly used gravity separation methods include heavymedium beneficiation, jig beneficiation and shaker beneficiation The beneficiation process of manganese oxide ore is generally to crush the ore to 60mm or 100mm, and then to classify, coarse grade particles are sent to jig mineral beneficiation jig separator for manganese processingThe oxide copper minerals are often porous, and in some cases they are watersoluble Some of the oxide minerals tend to slime during grinding, and flotation of fine oxide minerals is rather difficult Floatability of malachite is one of the most important oxide copper minerals for production of copper from oxide ores using flotation Cationic Handbook of Flotation Reagents: Chemistry, Theory and Practice