magnetic separator design

Magnetic separators Outotec

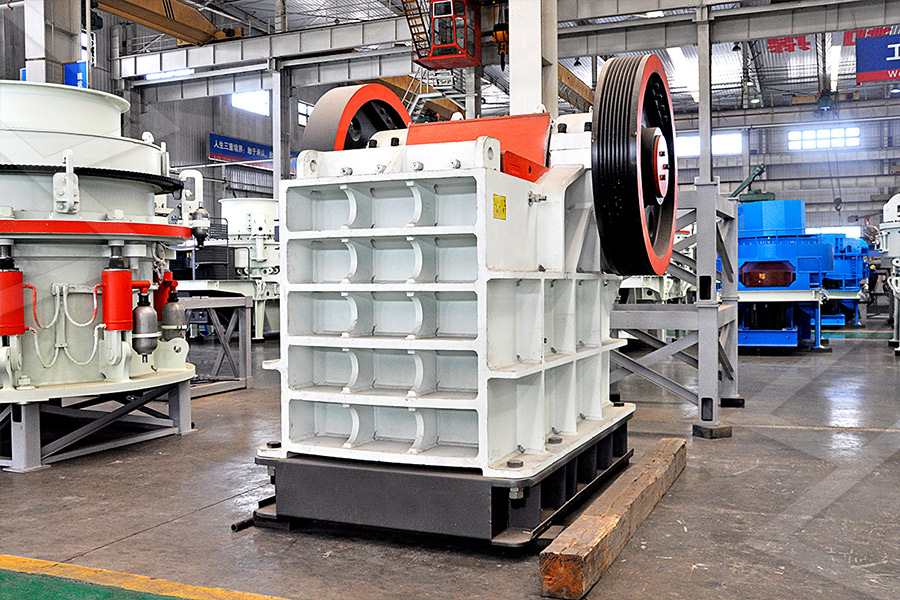

Outotec High Gradient Magnetic Separators (HGMS) are designed to recover weakly magnetic material from nonmagnetic matter and can be used for many applications The magnetic separator will be used in the cleaning house or prior to milling to remove ferrous parts such as nails, wire, screws, etc The product stream is distributed evenly over the entire Magnetic separators Components GroupASGCO ® ’s permanent overhead selfcleaning magnet separator is suspended over a conveyor or head pulley to remove ferrous metals Metal is attracted by the self cleaning model and is automatically and continuously removed from the Magnetic Separator Complete Conveyor Solutions

A Guide to Magnetic Separation Eclipse Magnetics

A magnetic separator applies basic magnetic principles to remove ferrous based and paramagnetic metals from a range of substances including powders, granules, liquids, pellets or pastes They are usually installed within the 07112005 The machine design incorporates the hopper assembly, framework, electrically powered belt conveyor, speed regulator and magnetic drum The design takes care of the feed discharge rate (fromDesign and construction of laboratory size magnetic These RED designs, similar to LIMS, are robust and typically offer high capacity and simple operation High intensity magnetic separators may be wet or dry High intensity dry Recent advances in magnetic separator designs and

MAGNETIC SEPARATORS kaneteccojp

A magnetic separator generating a high magnetic force of 26 T (26000 G) Used for weak magnetic substances which cannot be removed suffi ciently by a standard separator Magnetic selected process is a wet and dry joint dressing process for separation of magnetite, mainly used for threelevel magnetic separating processingThe magnetic field strength of design of magnetic separation processes KOOKSThe magnetic separator is a highly efficient fluid filtration method that removes high levels of ferrous contaminants from liquid, helping with recycle and reuse goals Low Maintenance The magnetic separator provides continuous operation and reduces downtime by up to 50% Value Prolongs toollife Improves surface finish of the component partMagnetic Separators PRAB

Magnetic Separator Complete Conveyor Solutions

ASGCO ® ’s permanent overhead selfcleaning magnet separator is suspended over a conveyor or head pulley to remove ferrous metals Metal is attracted by the self cleaning model and is automatically and continuously removed from the A magnetic separator applies basic magnetic principles to remove ferrous based and paramagnetic metals from a range of substances including powders, granules, liquids, pellets or pastes They are usually installed within the A Guide to Magnetic Separation Eclipse Magnetics29102018 An electro magnetic field is created by passing an electric current through a coil The design of the coil will dictate the strength and shape of the magnetic field Magnetic Separator Applications Magnetic Separation is Magnetic Separators Separation Equipment

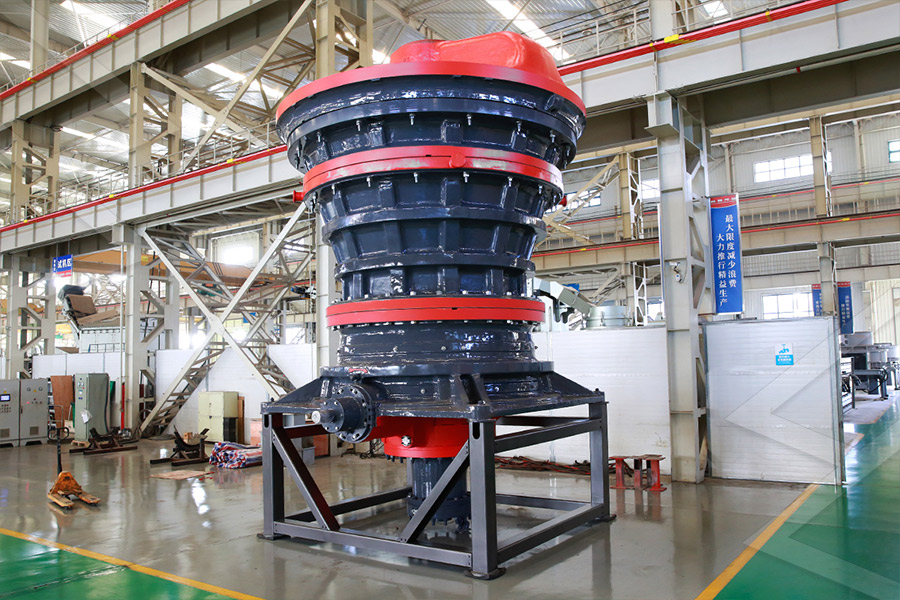

Intensity Magnetic Separator an overview ScienceDirect Topics

The design of such a roll magnetic separator is similar to that of the conventional roll magnetic separator, but it achieves a higher magnetic induction and its installation requires a much smaller occupation for space View chapter Purchase book Solid/liquid separation equipment ES Tarleton, RJ Wakeman, in Solid/Liquid Separation, 2007Magnetic Liquid Traps remove ferrous tramp including 400 series stainless steel and workhardened stainless steel from liquid processing and conveying lines Comes in several styles of traps with Highenergy, temperature compensated Magnetic Separation Equipment BuntingThese RED designs, similar to LIMS, are robust and typically offer high capacity and simple operation High intensity magnetic separators may be wet or dry High intensity dry magnetic separations are carried out with inducedroll (IRM) or rareearth roll (RER) magnetic separators, though the latter is far more common (Dobbins, Sherrell 2009)Recent advances in magnetic separator designs and applications

Magnetic Separators and Metal Detectors Eclipse

A single source for all your magnetic separation and metal detection needs Highquality separator design, manufacture,and guaranteed performance Compliance with required industry approvals eg ATEX and EHEDG Pre and 15022018 Separator Design In the design of the magnetic separator, the strength and the gradient of the magnetic field are two first order variables that affect mineral response The strength of the magnetic field or the field intensity refers to the number of lines of flux passing through a unit areaHigh Intensity Magnetic Separation Fundamentals96 well magnetic plate holder for isolating magnetic beads in a 96 well plate or for individual pcr tubes on the side racks After printing, 16 block magnets (K J magnetics cat no BX022) will need to be attached to the plastic (I used a craft glue called E6000, which should be used with a respirator or in the fume hood) ORIENTATION OF THE MAGNETS IS IMPORTANT You 96 well plate / 8 tube strip magnetic separator by

A Guide to Magnetic Separation Eclipse Magnetics

A magnetic separator applies basic magnetic principles to remove ferrous based and paramagnetic metals from a range of substances including powders, granules, liquids, pellets or pastes They are usually installed within the ASGCO ® ’s permanent overhead selfcleaning magnet separator is suspended over a conveyor or head pulley to remove ferrous metals Metal is attracted by the self cleaning model and is automatically and continuously removed from the Magnetic Separator Complete Conveyor SolutionsThe design of such a roll magnetic separator is similar to that of the conventional roll magnetic separator, but it achieves a higher magnetic induction and its installation requires a much smaller occupation for space View chapter Purchase book Solid/liquid separation equipment ES Tarleton, RJ Wakeman, in Solid/Liquid Separation, 2007Intensity Magnetic Separator an overview ScienceDirect Topics

Magnetic Separation Equipment Bunting

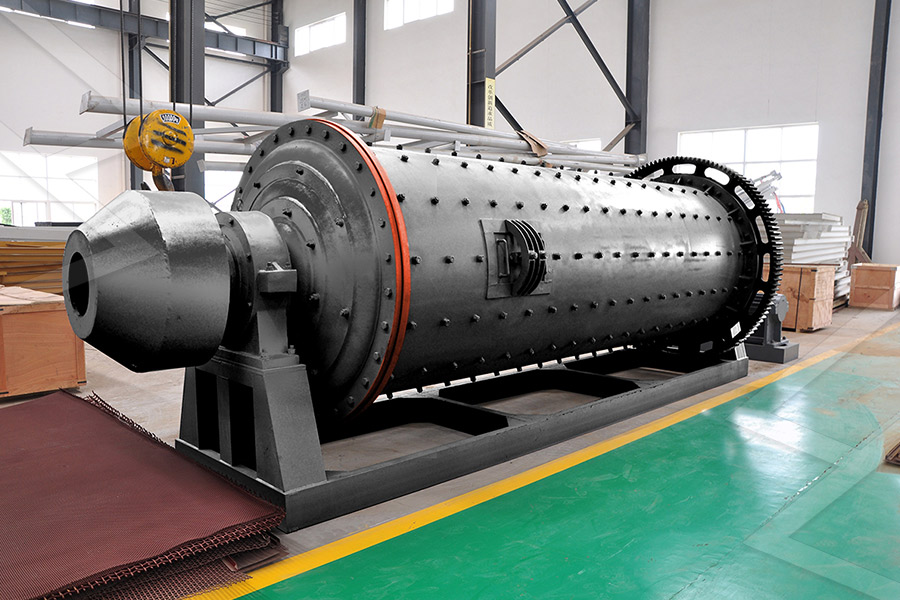

Magnetic Liquid Traps remove ferrous tramp including 400 series stainless steel and workhardened stainless steel from liquid processing and conveying lines Comes in several styles of traps with Highenergy, temperature compensated threedisc magnetic separators are divided into two types of dry threedisc highintensity magnetic separators the magnetic field intensity can be obtained by adjusting the magnetic field current of the magnetic disks to form different Three Disc Dry Magnetic Separator JXSC Machine has produced magnetic separators for dense media recovery since the mid1960’s Several hundred separators have been supplied since then for various operations on all continents Although praised for their high efficiency from the outset, the separators have over the years become even more effective with higher capacity ratings Designs Magnetic separators

Magnetic Separator Design

to be able to ideal satisfy client's requirements, all of our operations are strictly performed in line with our motto "high highquality, competitive price tag, fast service" for magnetic separator design, elastic separators , electrostatic separation of minerals , sink separator , the principle of our company is to provide highquality The pursue of the company, is definitely the clients' pleasure for Magnetic Separator Design, Besides there are also professional production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, highquality and highefficiencyMagnetic Separator DesignComponent for magnetic separators in various designs Manual cleaning Chute magnets For coarse powders and granules in freefall processes Very robust, free passage Manual or automatic cleaning Drum separators For Magnetic filtering separation Goudsmit Magnetics

Magnet traps / metal separator for powder flow A

Magnetic separators allow to remove metal contaminants from bulk solids flows Different design exist including rotary magnets or magnet drawers easily accessible for cleaning Please follow the link to get access to magnet theory